STA Zentrifugal-Separator A25

Privacy Policy

- Peeler nozzle for returning cleaned medium at 0.5 bar pressure

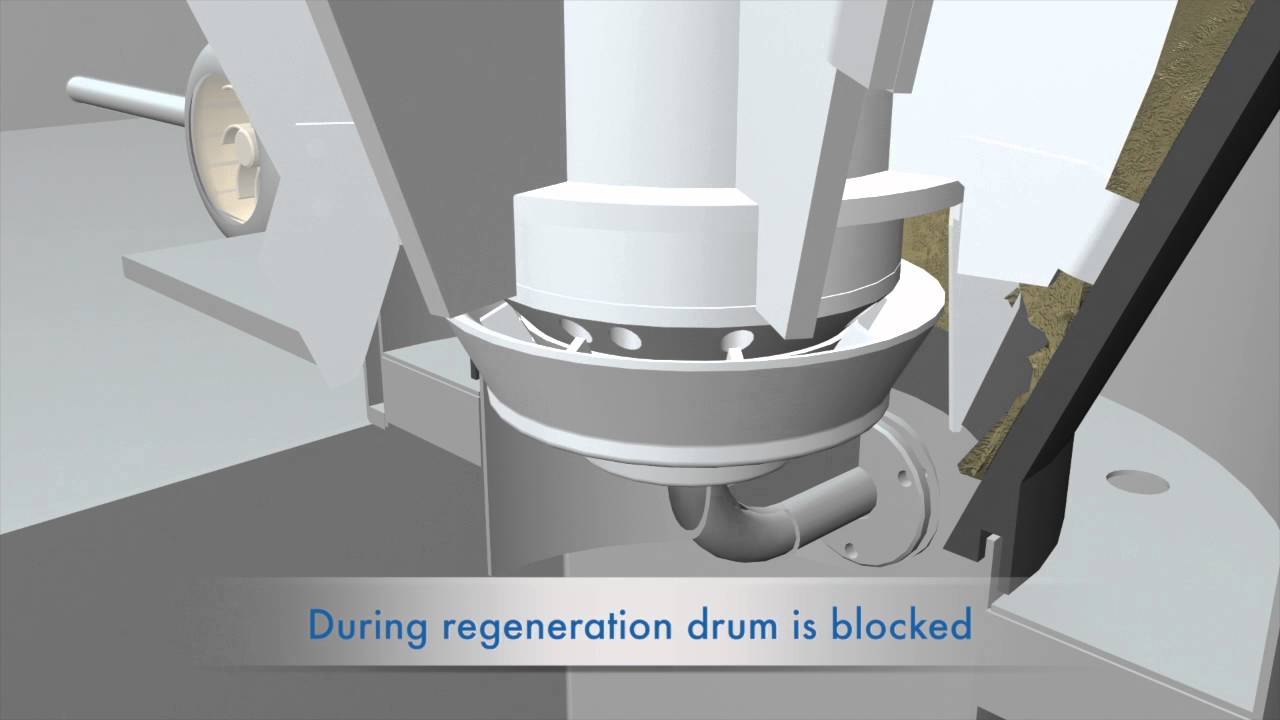

- Powerful scraper drive and wear-free magnetic clutch

- Sound- and vibration-damping double-jacket design

- Wear-free tungsten carbide-topped multi-scraper system

Fully automatically draining centrifugal separator for relatively high sludge quantities.

Application: Fine cleaning of industrial fluids with relatively high quantities of solids, for example in glass and ceramic processing, for paint sludge discharge in painting systems, in metal cutting, surface treatment baths, washing or vibratory grinding fluids, etc.

The drives: maximum performance and efficiency

The innovative drive concept responds to today’s demands for energy efficiency. The inverter controlled 100 Hz drive is more compact than ever, hence very silent and wearless. As an option power modules with low harmonics energy feedback can be used – saving money and improves solids discharge by even shorter breaking times.

Prepared for a tough job

STA Automatic Separators feature a robust and long-life design, and they are known for reasonable maintenance cost. For separating hard and abrasive solids, the accelerating and discharging components are furnished with a tungsten carbide antiwear coating. And should it ever become necessary the specially shaped blade tops can be changed even on-site.